SMART SCREW

SMART SCREW is the solution that allows screws, bolts, studs or other clamping devices to be interrogated about their mechanical characteristics and about their state of stress.

For the first time a screw, a bolt, a stud or other clamping equipment can be interrogated about their features and conditions. Thanks to this patented invention, clamping devices can now tell their mechanical characteristics because they’ve become intelligent!

In addition to the main measurement information about the clamping-component status, further data are available in the microchip, such as:

All information of the examined component is read wirelessly by simply approaching a special reading-system device to the head of the screw, bolt or stud.

TRACKING AND DATA MANAGEMENT

Each SMART SCREW device is equipped with a unique serial number, which allows the identification of each clamping element, without possibility of error, as well as track them through their entire life cycle.

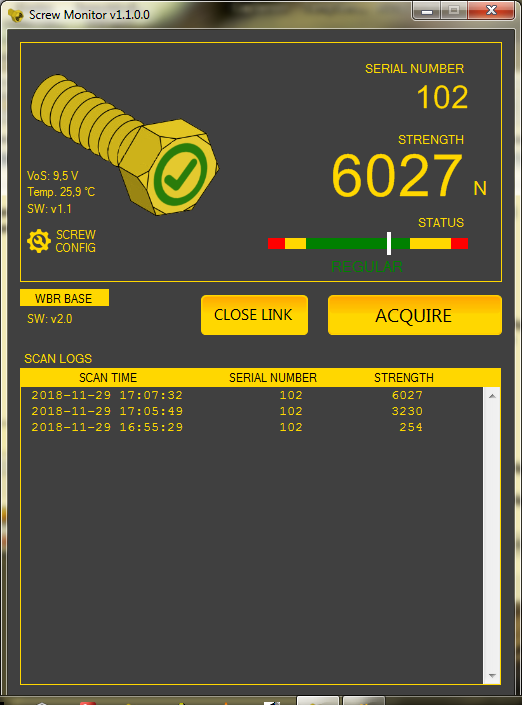

SMART SCREW READER is the reading system equipped with a touch head, which not only reads the torque data and characteristics of the tightening device, but also transmits them, via WiFi/Bluetooth/Modem/Serial, to a PC, to a database or cloud.

Thanks to this innovative system you will have the list of all the checks performed on the clamping elements (operation execution control) and the progress of torque values, in real time.

SAFETY

SMART SCREW can store information, including minimum and maximum tightening torque values. This allows the automatic check of clamping value, without the operator having to enter parameters or reference data.

The unique, unchangeable serial number associated with each SMART SCREW increases the safety of identification and traceability of each operation performed on the clamping element.

SMART SCREW DATA SHEET

Electronic parts dimensions: Diameter 12 mm - Height 5 mm

Maximum torque: Related to system mechanics

Operating temperature: -40 °C / +100 °C